When we speak of flow control mechanisms, especially in industries such as oil, gas, and water, we cannot sideline the importance of a check valve. What is it exactly? A check valve, also known as a non-return or one-way valve, allows fluid to flow through it in one direction only. It is vital equipment that prevents the fluid from flowing backward, therefore ensuring a smooth and efficient operation. Now, let us delve into its essential aspects in detail.

The Inner Workings of a Check Valve

From pipelines, pumps, to compressors, a check valve plays a vital role in numerous industrial systems. They operate automatically with the pressure alterations from fluid, gas, or steam. When the upstream pressure, also known as the inlet pressure, is greater than the downstream pressure, the valve opens. If the upstream pressure falls below the downstream pressure, the valve closes immediately to prevent backflow.

Varied Types of Check Valves

Depending on functions, loading conditions, and design particularities, check valves differ in their types. Here are the common types of check valves:

Swing Check Valves: Ideal for high-pressure operations, these valves come with a disc that swings on a hinge or shaft, permitting the flow forth and blocking it from reversing.

Ball Check Valves: They adopt a ball to block the flow and are typically used for both liquid and air applications.

Piston Check Valves: They contain a piston that moves to allow or stop the flow, best suited for high pressure and high-temperature systems.

Diaphragm Check Valves: These valves employ a flexing rubber diaphragm to control flow direction, effectively used in slurry applications.

Essential Applications of Check Valves

Across various industries, check valves serve many applications:

Water Supply Systems: Here, check valves prevent the reversal of flow, ensuring steady water supply and preventing contamination.

Fuel Supply Systems: They prevent backflow in fuel supply lines, securing the system from potential hazards.

Pumping Applications: In pumps, check valves halt reverse flow, protecting the pump from damage.

Chemical Processing Plants: They enable the safe and efficient operation of chemical processing systems.

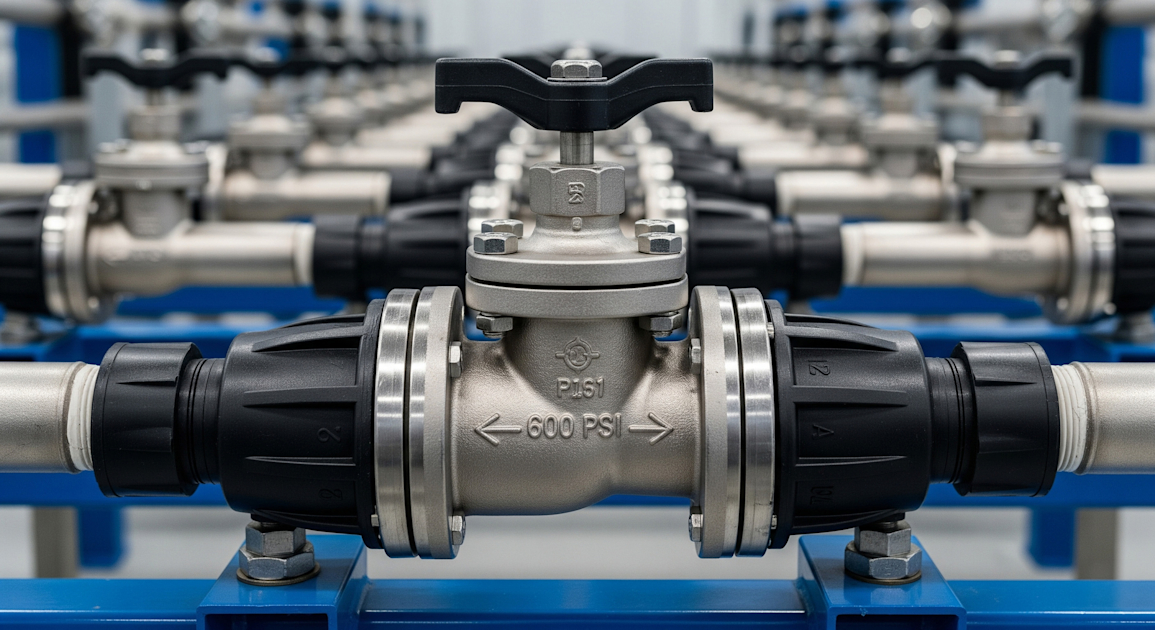

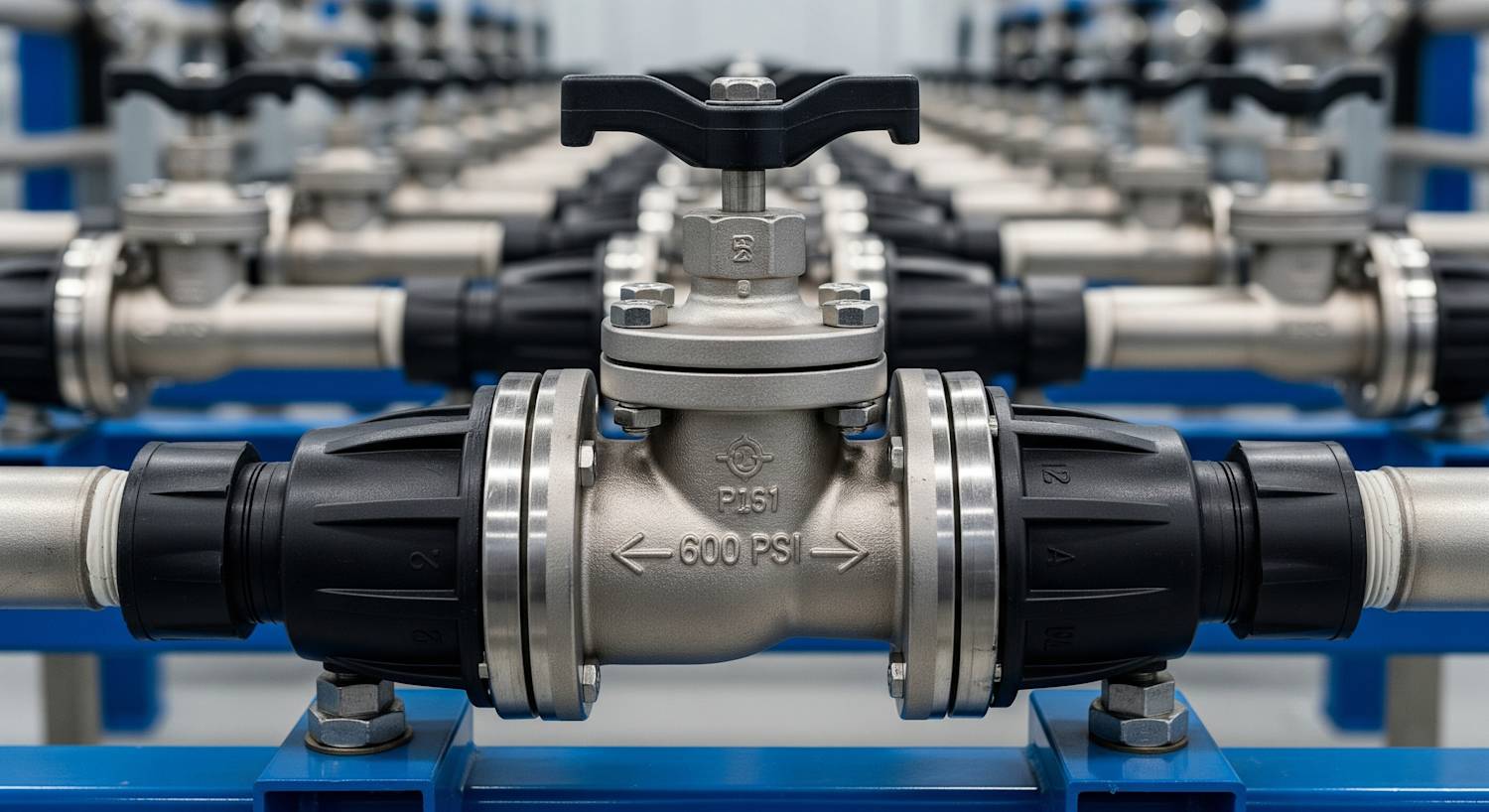

Instructions for Check Valve Installation

While check valves are relatively easy to install, certain best practices can enhance their performance:

- ● Always consider the valve’s pressure and temperature ratings before installing.

- ● Install the valve in the direction of the flow, represented by an arrow on the valve body.

- ● In cases of vertical pipework, ensure the fluid flows upwards for Swing and Piston check valves.

Frequently Asked Questions about Check Valve

Are There Different Types of Check Valves?

Yes, there are several types of check valves, each with specific uses and benefits. These include swing check valves, ball check valves, piston check valves, and diaphragm check valves among others. Their use depends primarily on the requirements of the application such as the type of fluid, the degree of backflow prevention needed and port size.

How Does a Check Valve Operate?

Check valves operate by using the flow velocity of the fluid to open and close. When fluid moves in the correct direction, it pushes against the valve, forcing it to open. Once the flow decreases or reverses, the valve closes to prevent backflow.

Where are Check Valves Used?

Check valves are utilized in a multitude of applications. They are often found in household systems like water heaters and sump pumps. In industrial settings, they're used in systems handling chemicals, steam, condensed air, water, oil and other materials. Utility systems, power plants, and wastewater management facilities also use check valves.

Can a Check Valve Fail? What are the Signs?

Like any other mechanical device, a check valve can fail due to a number of reasons such as wear and tear, poor maintenance, or improper installation. Symptoms of a failing check valve include leakage, excessive noise, or a reversal of fluid flow.

How can I Maintain my Check Valves Properly?

Regular inspection and maintenance of check valves ensure their proper functioning and longevity. This typically includes visually inspecting the valve for damages, leaks, or any noticeable issues. Functional inspections may involve checking the valve under working conditions. Any repair or replacements should be done by a trained professional.

What Factors should I consider when Selecting a Check Valve?

Several factors should be considered when selecting a check valve which include the type and pressure of the fluid, the size of the pipe in which it'll be installed, temperature, valve size, and the required opening and closing pressure. Other factors like the material of the valve and cost may also be considered.

What Sets Check Valves Apart from Other Valves?

Check valves differ from other types of valves in their operating principle. While most valves are operated manually or by sensors, check valves operate automatically. They depend entirely on the flow of the fluid they're regulating, which allows them to automatically prevent backflow.

Pros of a Check Valve

Easy Installation

Reduced Installation Costs

Check valves offer straightforward installation since they are typically self-automated. This simplicity can significantly reduce costs by limiting the amount of time installation professionals need to dedicate to the task. You also do not need any additional supports or bracing due to their lightweight nature, reducing the overall materials needed for installation.

Placement Flexibility

Most check valves are bi-directional, meaning they can be installed in anywhere in the pipe system—horizontal, vertical, or diagonal—which allows the user great flexibility. This is different from other types of valves, which often require a specific installation orientation to function properly.

Operational Efficiency

Lower Operating Costs

As a self-automated and non-electrically dependent valve, a check valve requires minimal operation and maintenance costs. The absence of exterior controls simplifies the maintenance process, making timely cost-effective check-ups possible.

Low Risk of Failure

With few moveable parts, the risk of hardware failure in a check valve is low compared to other valve types. This feature translates to a longer operational lifespan and less frequent replacement, providing both cost and time savings in the long run.

Control and Safety

Preventing Backflow

The main function of the check valve is to prevent backflow. This is extremely beneficial in protecting any upstream equipment, including pumps and compressors, from potential damage that could be caused by reverse flow.

Rapid Shut Off

Check valves provide a rapid shut off during times of backflow which ensures safety of the system. They react instantly as soon as the fluid or gas attempts to flow back, thereby safeguarding the entire system.

Cons of a Check Valve

Design Limitations

Pressure Limitations

Check valves can only handle a limited amount of pressure, especially compared to other types of valves. These pressure limitations could restrict the type of applications that the check valve can be safely used for.

Size Limitations

Check valves are also typically smaller and may not be suitable for large pipe systems, which may require larger and more robust valves to manage significant fluid or gas volumes.

Operational Challenges

Noise Issues

Check valves have a tendency to generate noise and vibrations, especially in high-flow applications. This can be a nuisance in residential areas or in environments where silence is needed.

Water Hammer Effect

Water hammer, a phenomenon that occurs when a fluid in motion is forced to stop or change direction suddenly and could potentially damage the pipe system, is commonly observed with check valves. It happens because the check valve reacts so quickly to prevent backflow, causing a sudden stop in the fluid motion.

Maintenance and Longevity

Difficulty in Repair

Check valves have compact designs, which, although beneficial from an installation perspective, can make them difficult to repair. If damage occurs, it generally means that the entire valve must be replaced, which is not as cost-effective as simply replacing a broken component.

Wear and Tear

Check valves experience a lot of wear and tear due to the constant motion of the flap or disc inside. This means they might have to be replaced more frequently than other valve types. The failure of a check valve can also lead to a cascading failure in a system if backflow is not anticipated or accounted for, leading to substantial repair costs.

Myths and Misconceptions about Check Valves

In the world of plumbing and fluid systems, check valves play a critical role. They allow fluid to flow in one direction and prevent it from flowing back in the opposite direction, therefore enhancing the efficiency of many systems. However, despite their straightforward operation, a series of myths and misconceptions exist around check valves. In this section, let's debunk these misunderstandings.

Myth 1: All Check Valves Work the Same Way

Reality

Not all check valves operate on the same principle. While they share a common purpose – that of allowing flow in one direction only – the way they achieve this can vary. Some common types of check valves include swing check valves, lift check valves, and ball check valves, each with their unique mechanisms and ideal applications.

Myth 2: Check Valves Don’t Require Maintenance

Reality

Contrary to the belief that check valves are "install and forget" devices, they do require consistent maintenance. Over time, wear and tear can cause the valve to stop functioning properly, leading to backflow issues and other operational problems. Regular maintenance ensures the valves continue to function optimally and last longer.

Myth 3: Any Check Valve Can Be Used for Any Application

Reality

The type of check valve to be used largely depends on the application it’s needed for. Different designs of check valves are suited to different types of fluid, pressure ranges, and velocity of flow. It's essential to select a check valve that aligns with the specific requirements of your system.

Myth 4: Check Valves Can Completely Prevent Backflow

Reality

While check valves are designed to prevent backflow, no valve can achieve 100% efficiency. Some amount of leakage or reverse flow can still occur due to wear, a drop in pressure, or if particles get caught in the valve. That's why routine maintenance and inspections are crucial.

Myth 5: It's Impossible for Debris to Affect a Check Valve

Reality

While check valves are robust and designed to withstand tough conditions, small particles and debris can get lodged within the valve, affecting its operation. It’s crucial to ensure that the fluid flowing through the valve is as clean as possible to prevent issues.

Myth 6: All Check Valves Make a Water Hammer Noise

Reality

The 'water hammer' noise, a loud, banging sound, is often associated with check valves. However, not all check valves create such a noise. The water hammer effect is often caused by a sudden halt in the water's momentum, which certain types of check valves are better at managing. Using the correct valve for your system, and installing it correctly, can mitigate this problem.

Myth 7: The Size of the Check Valve Doesn’t Matter

Reality

The size of a check valve plays a crucial role in its performance. A valve that is too small might get overwhelmed and fail, while one that is too large might not seal properly. The size of the valve must perfectly correspond to the size of the pipe it’s being installed in to ensure optimal performance.

Myth 8: Every Check Valve Requires a Manual Override

Reality

The function of a manual override in a check valve is to manually open the valve. However, not every check valve needs to have a manual override. For instance, in systems where the flow is continuous, a manual override would rarely, if ever, be used.

Myth 9: Check Valves Can’t Be Used in High-Pressure Systems

Reality

Some people believe that check valves are not suited for high-pressure systems. While it’s true that certain types of check valves (for example, swing check valves) might have limitations in high-pressure systems, other types, like ball check valves, are designed to handle high-pressure environments.

We have unraveled the fabric of misconceptions surrounding check valves. As we can see, understanding the full capabilities and limitations of these essential components can greatly improve the selection, maintenance, and application of check valves in a fluid system.

Summary

Check valves are definitely the unsung heroes of plumbing systems. They singlehandedly prevent water, gas, or any other fluid from flowing back into your pipes, which could cause some serious havoc. When it comes to safeguarding your home or any industrial set-up from potential damage and ensuring everything runs smoothly, you can't overlook the importance of a check valve.

The simplicity and functionality of a check valve often get taken for granted. Its concept is so simple - allowing fluid to flow in just one direction, and yet its impact is massive. In the grand scheme of things, a check valve is what stands between a well-oiled machine and a potential disaster. Just like you wouldn't want your car to lose brakes, you wouldn't want your plumbing system without a check valve.

So, the next time you turn on your faucet or flush your toilet, keep in mind how crucial a tiny piece of equipment like the check valve can be. It may be small, but it does a lot more than meets the eye. Its variety of designs cater to different requirements, making it flexible for various applications. Indeed, a check valve is a testament to the fact that big things often come in small packages.

About KYPD Plumbing

KYPD Plumbing is your local, family-owned plumbing company in Lexington, KY. We've been comforting homeowners and business owners with our topnotch plumbing services since 2005. With a team of proficient and licensed plumbers, we take pride in quickly diagnosing and fixing any sort of plumbing problem- from leaks and clogs to installations and inspections. Choosing KYPD Plumbing means choosing quality, convenience, and personable service. Our commitment is to deliver nothing but the best professional expertise and customer service around the clock. Get in touch with us for all your Lexington, KY plumbing needs.

Tags: valves, plumbing, fluid control,